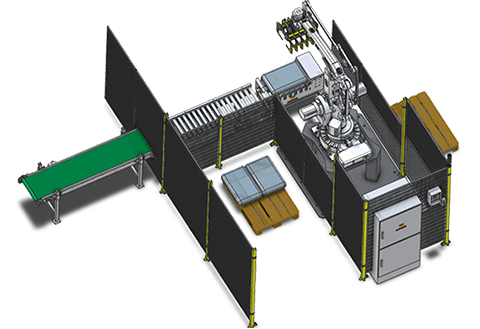

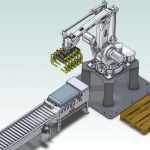

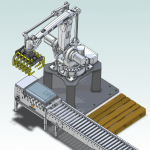

Fixed palletising station

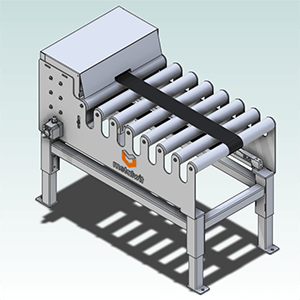

robot base, gripper, belt conveyor, levelling rollers, roller conveyor, fencing and safety system

Safety

CE Marking

The palletising station has the CE mark (meets all requirements of the New Approach directives) and the EU declaration of conformity, thus meeting the basic applicable quality and safety standards:

- in accordance with the relevant requirements of EU harmonisation legislation: 2006/42/EC, 2014/30/EU, 2014/35/EU

- in accordance with the harmonised standards: PN-EN ISO 10218-1:2011, PN-EN ISO 10218-2:2011, PN-EN ISO 14120:2015, PN-EN ISO 13850:2016

METALWIT Robots nameplate

Robotic bagging

Safety System

In order to reduce the risk of dangerous situations, the workstation is equipped with fixed guards, as well as safety barriers and light curtains eliminating the risk of people getting into the robot’s work area.

Application

Flexibility

- printer

- weight

- positioners

- etc.

Technical specification

performance

up to 400 bags per hour

product weight

up to 70 kg

pallet height

up to 1.9 m

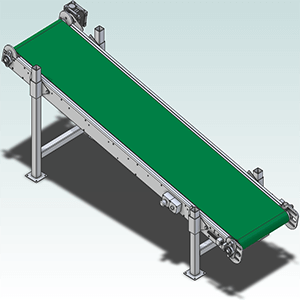

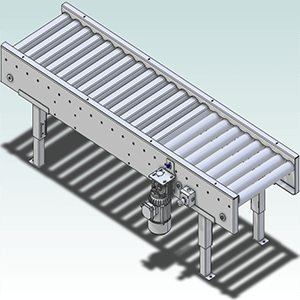

conveyor dimensions

length 1.0 – 2.5 m

height 0.6 – 1.0 m

width 0.4 – 0.7 m

Features

Configurable layout

We will adjust the layout of the station in the most optimal way, regardless of the space at hand.

Fast lead time

We can deliver your order within 5-6 weeks or faster!

Easy programming

The customer uses presets (ready-made programs) by our programmers. Thanks to this, a two-day training will be enough to master the robot’s controls

Different product types

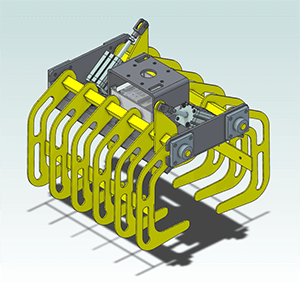

The conveying system and robot gripper will be adapted to the product.

Can be used simultaneously in different areas

The station can be applied in metal, wood, food, furniture and other industries.

Cooperation with other machines

The robot can be integrated with a milling machine, press brake, injection moulding machine or other machinery.

Possibility of arranging products according to complex patterns

It does not matter whether the system of stacking products on the pallet will be permanent (regular) or will change e.g. due to changes in product dimensions or pallet dimensions. Our programmers like challenges!

Possibility of expanding the station with additional functions

The station may also perform other tasks such as quality control or labelling.