Why should you opt for an automation system?

Robots never take breaks, have no phones, no meetings, no days off or holidays. They never fail, they never disperse, and they ensure consistent quality. They work continuously until you tell them otherwise, and modern industrial robots require minimal maintenance.

Better use of operator time. Instead of loading and unloading products manually, the operator can perform other activities while the robots reliably perform their procedures.

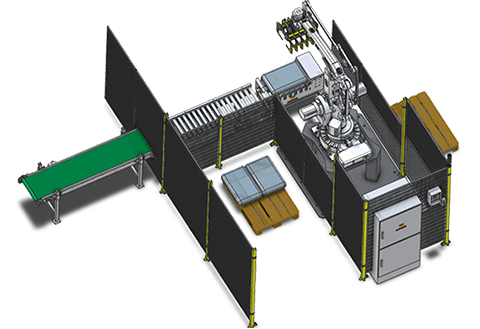

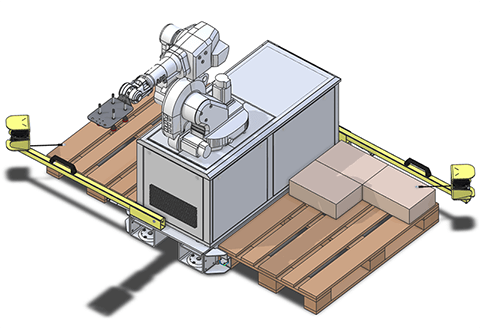

More accessible than ever. These days, robotised cells have low initial costs, are easy to install and operate, do not require advanced programming skills and can work faultlessly for many years.

Three myths about robotization

- Myth 1

“Programming robots is difficult, and we don’t have that competence.”

Prepared robot stations with PLC control and an easy to use HMI touch screen allows any machine operator to click and select a preloaded program to start the machine. No programming knowledge is required. For those who want to learn programming, we have prepared a 20h course, after which they will be able to write programs freely.

- Myth 2

“We cannot afford expensive automation systems.”

Although custom automation systems can be quite expensive, the cost of stand-alone robotic units is surprisingly low. These devices are also easy to install (determination of position in relation to the conveyor, floor anchoring, power supply, compressed air and Ethernet connection). At an average cost of €55,400 per station, the monthly maintenance should not exceed €989 (with the possibility of working three or four shifts).

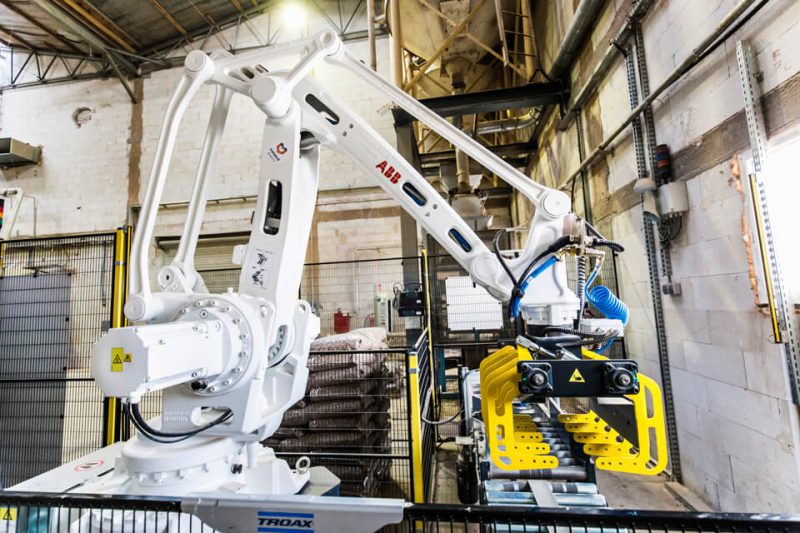

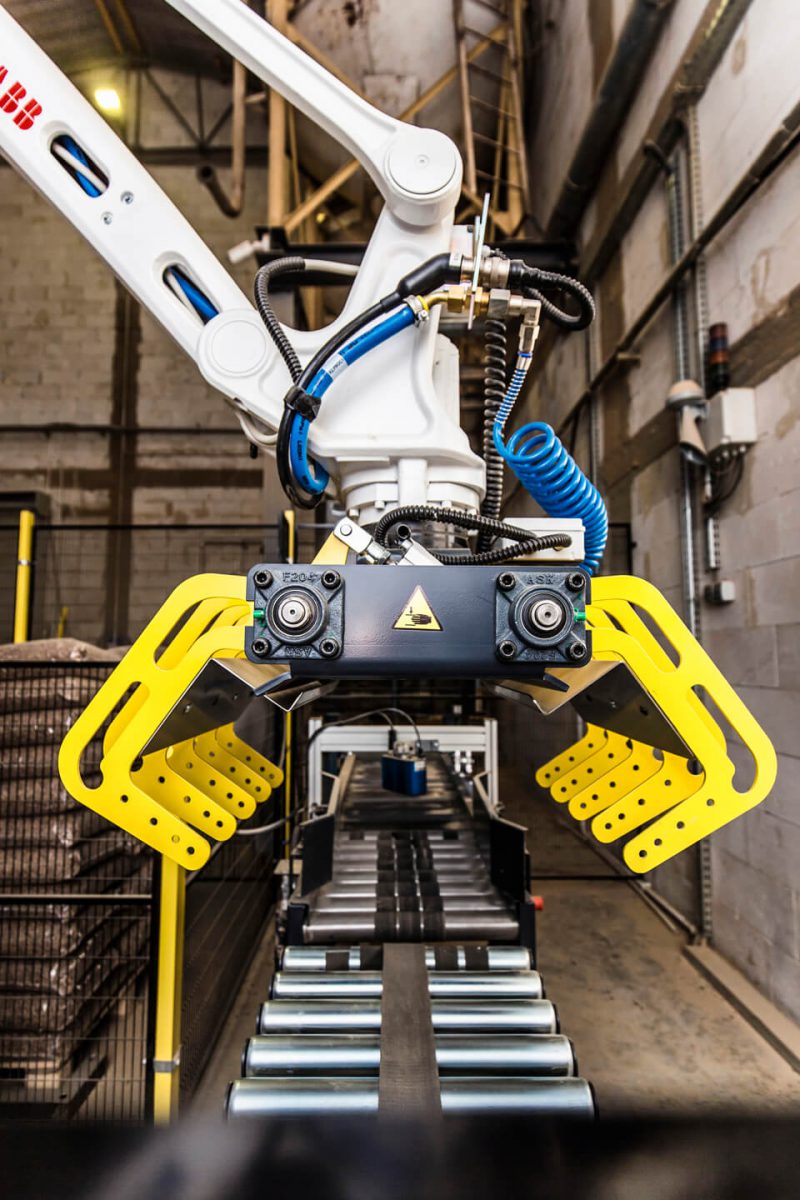

ABB palletising robots are proven 4-axis machines. The limited number of axles and gears reduces the risk of failure. Therefore, the costs of periodic inspections are lower and the use of oils instead of greases in transmissions extends the intervals between lubricant changes to an average of every 20,000 operating hours. These are significant savings – in terms of total cost of ownership of the automation system.

- Myth 3

“We do not produce large batches, so robots won’t really help.”

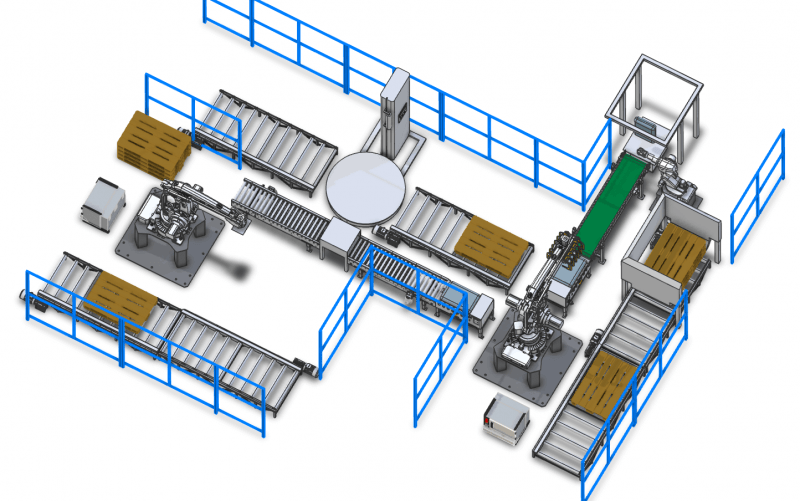

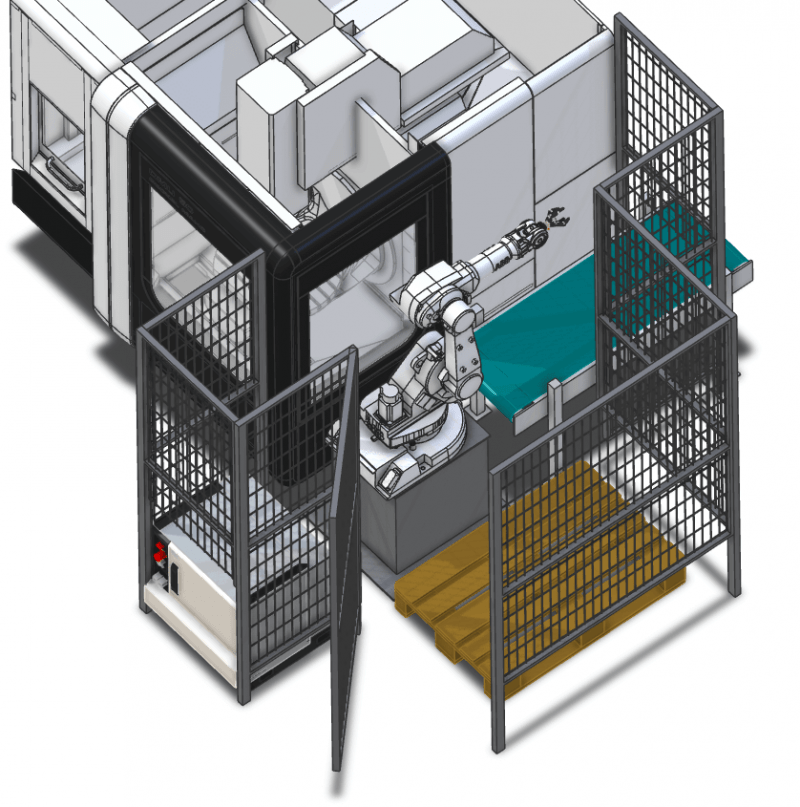

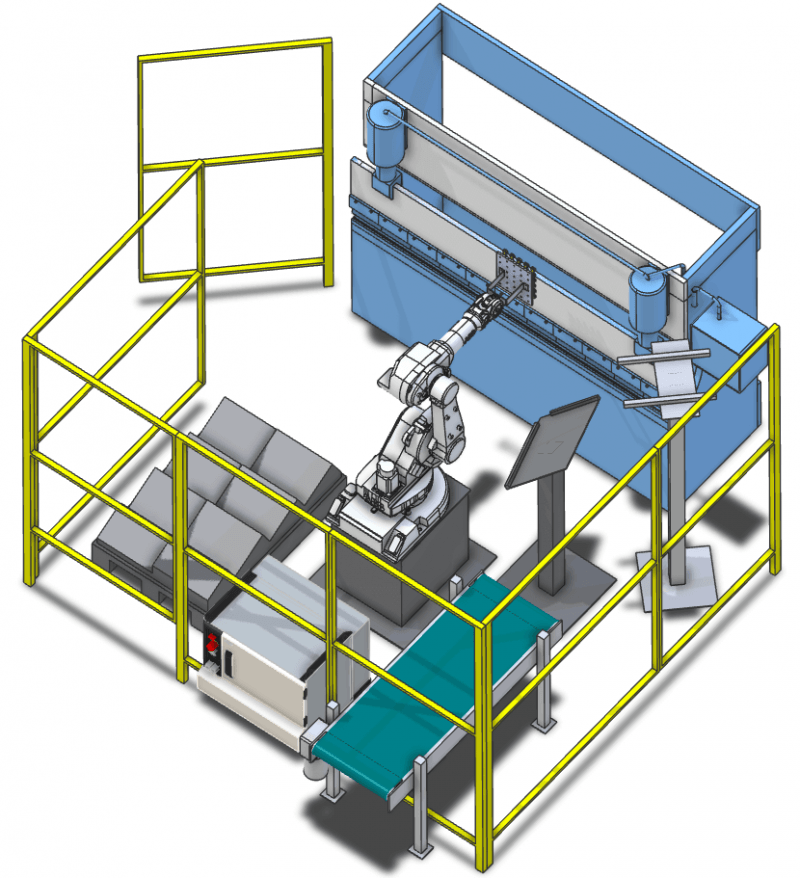

Robotic solutions are designed for production flexibility. Where many products are manufactured in small batches, the main goal is to quickly change the tool format. Choosing the right gripping system and creating a program that is suitable for palletizing various products reduces machine downtime and reduces the number of operators working in three shifts. This means that there can be more than one palletising station within one cell, which is a great advantage for small spaces. Retooling the station by means of the operator panel very often consists only of changing the laying pattern. An additional advantage is to avoid the need to accumulate unnecessary stock.

Return on Investment

Automation brings benefits in the following spheres:

Costs

Fewer people are needed, which leads to savings on labour.

Production

Due to the stability of production, you will produce up to 20% more per hour, and you can also produce longer, which means that the machines will run for 12, 16 or even 24 hours.

Effectiveness

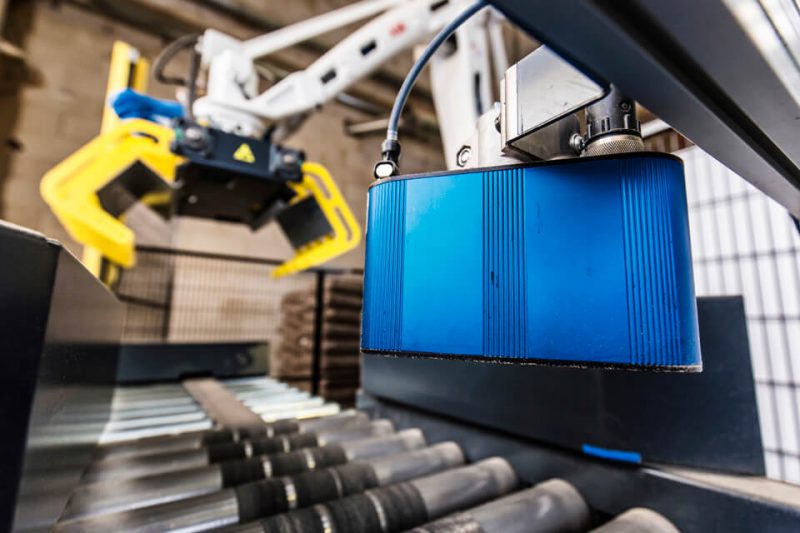

It leads to the elimination of deficiencies by using auxiliary equipment such as load cells and optical sensors. In addition, it should be noted that robotization forces better work organisation.

As you can see, these effects significantly reduce costs, while increasing production and efficiency. The additional benefits of these effects are: higher operating profit and lower market price, which ultimately makes the company more competitive.

Gallery

Who are we?

Metalwit Robots is created by people who do their work with passion and commitment. Knowledge and skills combined with a friendly atmosphere in our team allow us to solve even the most complex problems. Nothing is impossible to us!

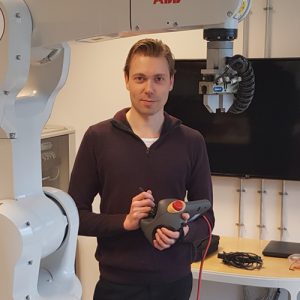

Our team

Łukasz

Monika

Tomasz

Monika

Michał

What do we do?

Our goal is to construct and deliver modern automation and robotics solutions. We approach every client in a creative and specialized way, taking into account their requirements and the benefits they may gain from implementing a given solution.

You are not sure if robotization is for you? You want to know more?

Tel:

+48 606 296 004

Metalwit ROBOTS

Lipniki, ul. Akacjowa 16

86-005 Białe Błota

E-mail:

robots@metalwit.pl