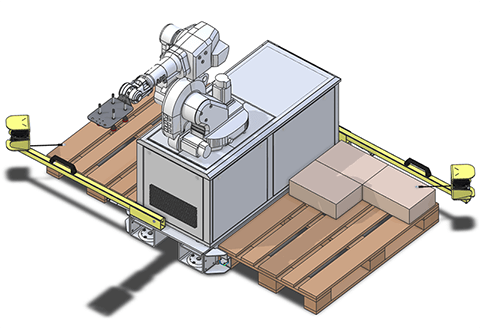

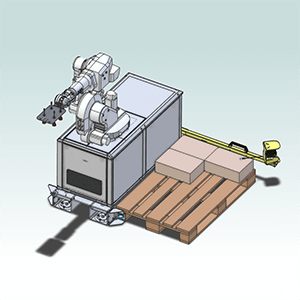

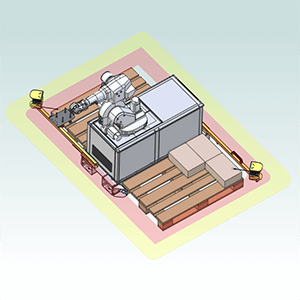

Mobile palletising station

robot base, gripper, SKK safety scanners, Siemens PLC control, SMC valve island

Safety

CE Marking

The palletising station has the CE mark (meets all requirements of the New Approach directives) and the EU declaration of conformity, thus meeting the basic applicable quality and safety standards:

- in accordance with the relevant requirements of EU harmonisation legislation: 2006/42/EC, 2014/30/EU, 2014/35/EU

- in accordance with the harmonised standards: PN-EN ISO 10218-1:2011, PN-EN ISO 10218-2:2011, PN-EN ISO 14120:2015, PN-EN ISO 13850:2016

METALWIT Robots nameplate

Robotic bagging

Safety System

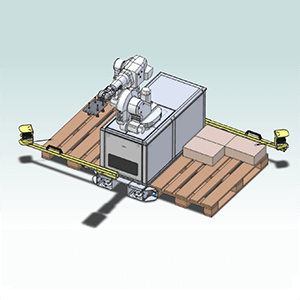

With safety and convenience in mind, we offer a choice of one of the options:

- station equipped with guards, light curtains and safety barriers

- station equipped with safety laser scanners, which allows for greater mobility and a large safety area

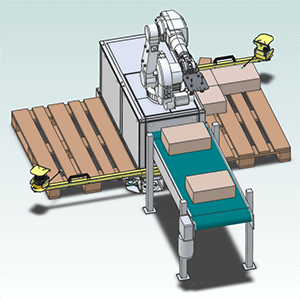

Application

Flexibility

- Conveyors

- printer

- weight

- positioners

Technical specification

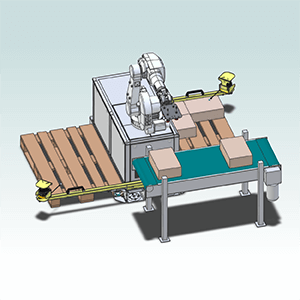

performance

up to 500 packages per hour

product weight

up to 10 kg

pallet height

up to 1.6 m

mobile station dimensions (without pallets)

0,60 x 1,29 x 0,58m

Features

Compact dimensions

The robot with platform and control cabinet are placed in one small mobile station.

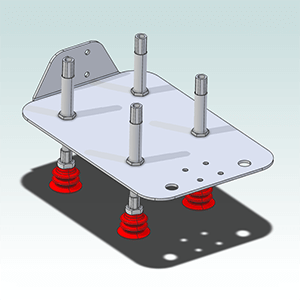

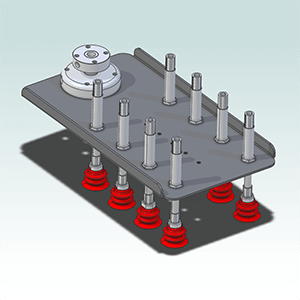

No need for fencing

The station may be equipped with safety scanners entirely replacing guards, light curtains and safety barriers.

Simple relocation of the structure

Thanks to its small size, the station takes up little space and can be easily adapted to the workplace.

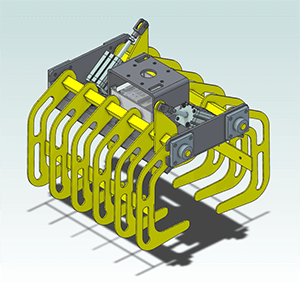

Quick & convenient retooling

Preparation of the station, i.e. setting up the station, program, speed and clamp attachment is carried out efficiently and quickly.

Easy programming

Dedicated “Last inch” software allows the operator to modify the basic parameters efficiently.

The station can be applied in metal, wood, food, furniture and other industries.

Cooperation with other machines

The robot can be integrated with a milling machine, press brake, injection moulding machine or other machinery.

Possibility of arranging products according to complex patterns

It does not matter whether the system of stacking products on the pallet will be permanent (regular) or will change e.g. due to changes in product dimensions or pallet dimensions. Our programmers like challenges!

Safety at work

The station has a declaration of conformity and a CE mark.